Paper machine measurement – precision meets efficiency

In today’s world, where systems are operated ever faster and at the same time more reliably, our paper machine measurement sets standards. Our expertise in precise alignment enables us to bring paper machine roll sections into a low-maintenance and low-wear condition using state-of-the-art technology. Whether you need to optimize paper draws, align wire sections or determine the exact outlet geometry of a headbox – we are your partner.

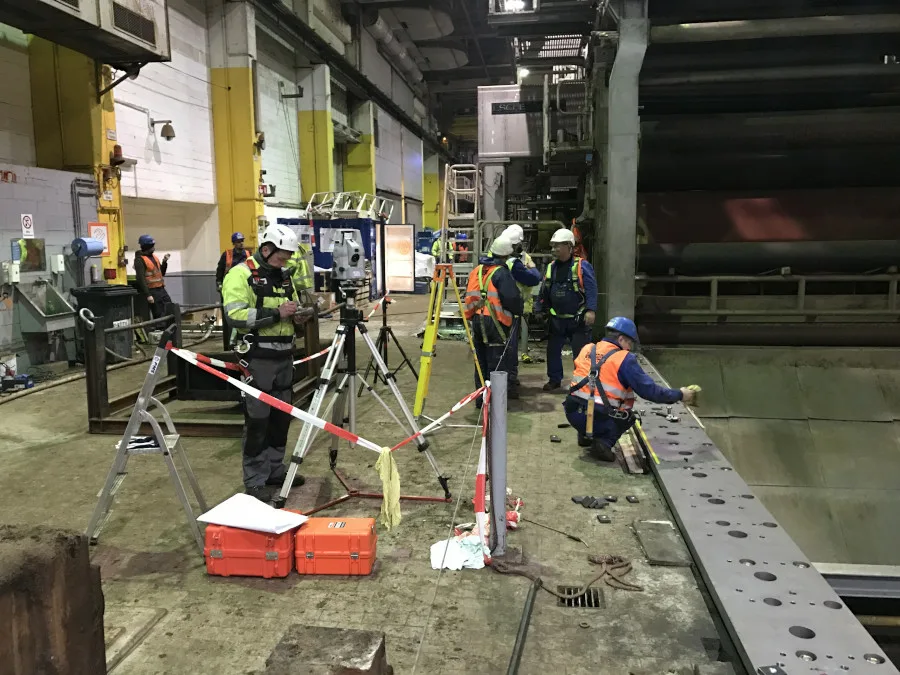

With the use of our state-of-the-art laser trackers, motorized 3D total stations, combined with the respective special software and targets developed in-house specifically for the requirements of the paper industry, we guarantee first-class results. Our portfolio is complemented by the use of traditional theodolites and precision levels. But our philosophy is: as precise as necessary, as cost-efficient as possible. We are familiar with the challenges of older systems and are ready to discuss solutions with you.

Our expertise goes beyond pure surveying. As trained mechanical engineers, we pride ourselves on not leaving you alone with documented results. If required, we can take over the complete alignment of your system. Together with you, in a holistic view of the system, we determine the necessary measures.

Inspection of axles and their adjustment

We carry out inspections in all areas of the paper industry. In addition to the conventional very wide bulk paper machines, we are also familiar with special machines such as winding board machines with single-sheet flat presses, inclined wire machines, security machines, leather fiber machines, filter mat machines and their specifics.

Poor alignment of individual machine components can lead to various operating problems:

- Shorter service life of machine clothing,

- Reduced service life of roller coverings,

- Shortened service life of rolling bearings,

- Wear on cylinder and roller surfaces,

- Inconsistent drainage,

- Increased vibration of individual machine parts,

- Shorter service life of clutches and drive shafts,

- Shorter service life of scrapers,

- Increased energy consumption.

These deviations have a direct impact on the quality and cost of the end product and the entire technological process.

Our promise: expertise and a comprehensive overview every step of the way.

Do you have any questions or would you like an individual offer?

PMS Weichelt GmbH

Managing Director Maik Weichelt

Error: Contact form not found.