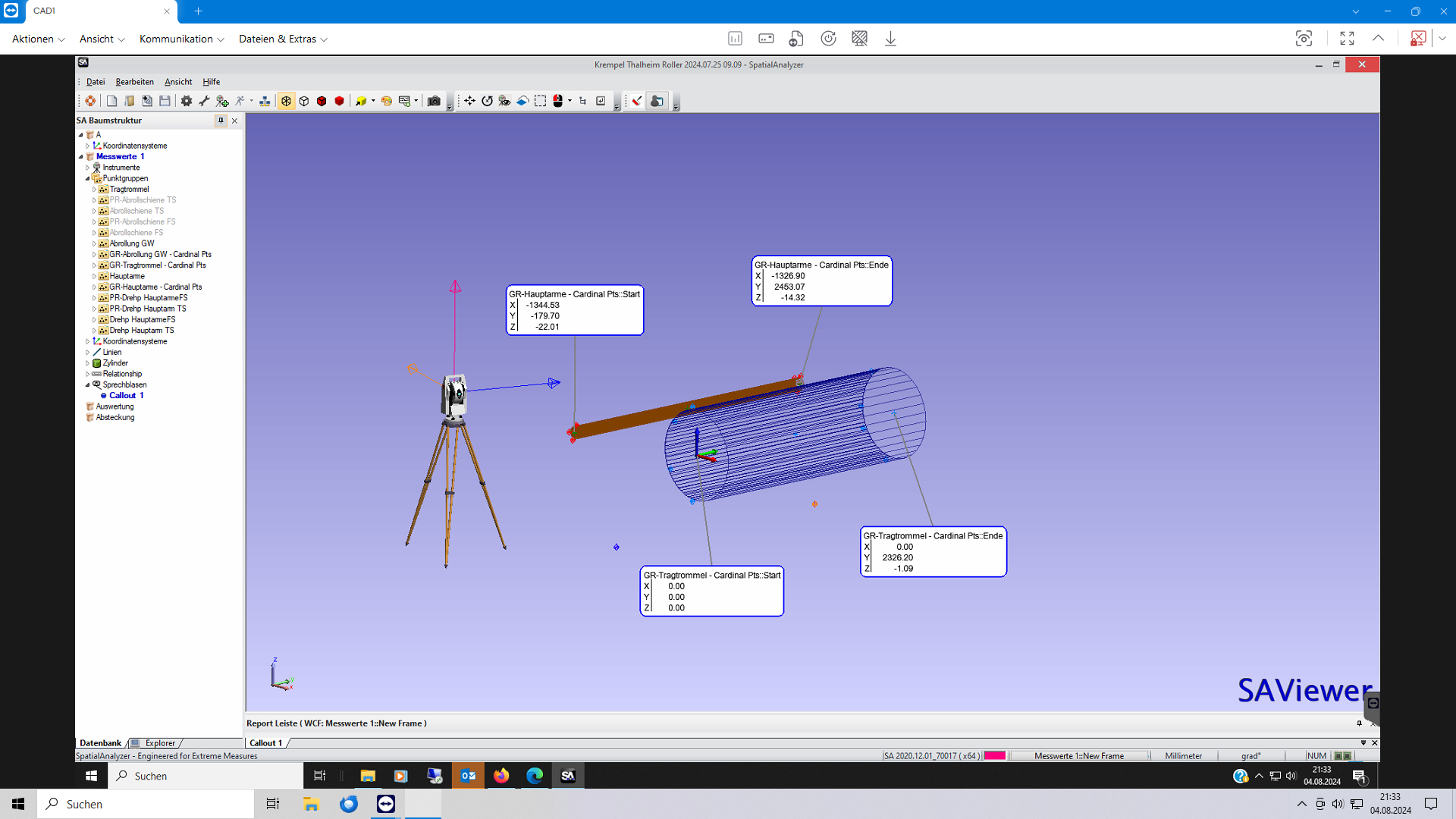

For many older systems in the paper industry, poorly aligned system components become a problem over the years. We were recently called to a board machine to measure the felt rollers in the press section. When asked why and what the problem actually was, reference was made to the extremely poor position of the cardboard track in the KM. The cardboard web would have to be “controlled” via the differential pressure of a horizontal press in order to be able to roll up the web properly at the Pope. So far so good. The measurement of the approx. 40 rollers with drawn-in clothing took approx. 1 1/2 days and showed the usual axial deviations of older machines of up to 3 mm on the web surface of the rollers. This could not be the problem. So we took measurements at the point where the problem was visible on the Poperoller. And lo and behold, despite the cross shaft, the pressure rollers of the auxiliary arms were 18 mm! out of alignment with the carrier drum and their pivot points were also 4 mm out of angle, in short the paper roll on the reel spool had extremely different winding hardness across the web, which also changed as the diameter of the roll changed. This was followed by the alignment incl. measurement protocol and everyone was happy that the problem, which had been causing major problems for some time, had been found. PMS Weichelt GmbH has been a reliable partner to the paper industry for many years when it comes to measuring and aligning existing machines.

For many older systems in the paper industry, poorly aligned system components become a problem over the years. We were recently called to a board machine to measure the felt rollers in the press section. When asked why and what the problem actually was, reference was made to the extremely poor position of the cardboard track in the KM. The cardboard web would have to be “controlled” via the differential pressure of a horizontal press in order to be able to roll up the web properly at the Pope. So far so good. The measurement of the approx. 40 rollers with drawn-in clothing took approx. 1 1/2 days and showed the usual axial deviations of older machines of up to 3 mm on the web surface of the rollers. This could not be the problem. So we took measurements at the point where the problem was visible on the Poperoller. And lo and behold, despite the cross shaft, the pressure rollers of the auxiliary arms were 18 mm! out of alignment with the carrier drum and their pivot points were also 4 mm out of angle, in short the paper roll on the reel spool had extremely different winding hardness across the web, which also changed as the diameter of the roll changed. This was followed by the alignment incl. measurement protocol and everyone was happy that the problem, which had been causing major problems for some time, had been found. PMS Weichelt GmbH has been a reliable partner to the paper industry for many years when it comes to measuring and aligning existing machines.